PLMS Screw nut

Reliability in terms of safety.

This accessory is often used for pewag winner lifting points with special and maximum lengths.

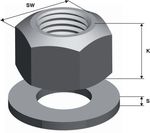

For sizes M8 up to M48 this accessory is available as a set: The nut is manufactured according to DIN 980 V in strength category 10. A washer completes the set.

From size M56, the nut is 1.5 times as high and manufactured according to DIN 6331. An additional washer is not required here.

Note:

Nuts according to DIN 980V are self-locking nuts, i.e., with a clamping part. This clamping part is responsible for securing the nut (against loosening the nut). They are used when the screw length is only slightly longer than the load thickness (e.g. calculated according to pewag specifications).

If the bolt is much longer than the load (e.g. use the nut for different load thicknesses and bolt protrusions) then it can be tedious to always install and loosen these nuts with a tool. In this case, the use of a nut according to DIN 6331 is preferable. However, you should always check the correct, tight fit of the nut before each lifting operation.

Tableau des spécifications

| PLMS Screw nut | Code / Type | thread [mm] |

Thread pitch P [mm] |

SW [mm] |

K [mm] |

S [mm] |

VPE [piece] |

|---|---|---|---|---|---|---|---|

|

PLMS 8 | M8 | 1,25 | 13 | 8 | 1,60 | 10 | PLMS 10 | M10 | 1,50 | 17 | 10 | 2 | 10 | PLMS 12 | M12 | 1,75 | 19 | 12 | 2,50 | 10 | PLMS 14 | M14 | 2 | 22 | 14 | 3 | 10 | PLMS 16 | M16 | 2 | 24 | 16 | 3 | 10 | PLMS 18 | M18 | 2,50 | 27 | 18 | 4 | 10 | PLMS 20 | M20 | 2,50 | 30 | 20 | 4 | 10 | PLMS 24 | M24 | 3 | 36 | 24 | 4 | 10 | PLMS 30 | M30 | 3,50 | 46 | 30 | 5 | 4 | PLMS 36 | M36 | 4 | 55 | 36 | 6 | 1 | PLMS 42 | M42 | 4,50 | 65 | 42 | 7 | 1 | PLMS 48 | M48 | 5 | 75 | 48 | 8 | 1 | PLMS 56 | M56 | 5,50 | 85 | 84 | - | 1 | PLMS 64 | M64 | 6 | 95 | 96 | - | 1 | PLMS 72 1) | M72 | 6 | 105 | 108 | - | 1 | PLMS 80 | M80 | 6 | 115 | 120 | - | 1 | PLMS 90 | M90 | 6 | 130 | 135 | - | 1 | PLMS 100 | M100 | 6 | 145 | 150 | - | 1 |

| 1) Nut acc. to DIN 6331 - no washer | |||||||